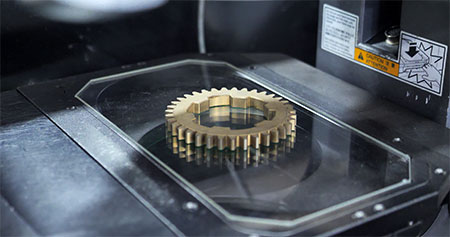

At Sintergy, we have a broad range of equipment that allows us to manufacture virtually any part and/or assembly for our valued customers. This includes state-of-the-art presses, sintering furnaces/ovens, inspection tools, and much more. Below is a listing which shows the range of our equipment and capabilities. In addition, we practice processes that foster environmental responsibility throughout our manufacturing operations.

State-of-the-Art Presses ranging from 20 tons – 750 tons to accommodate various types and designs of parts and assemblies. Continuous Sintering Furnaces ranging from 14 inch – 24 inch. Since 2018, our secondary area has been growing at a rate requiring the additional floor space. With several CNC lathes, multiple machining centers and including dual spindle turning centers.

Many specific Quality Inspection Tools and Equipment ensure that our products will meet customers' specifications. We use several in process inspection stations, empowering all employees to verify the quality of our products to meet the customers requirements for every shift seven days a week!

- State-of-the-Art Presses ranging from 20 tons – 750 tons to accommodate various types and designs of parts and assemblies.

- Continuous Sintering Furnaces ranging from 14 inch – 24 inch; we also offer multiple treatments and platings.

- Many specific Quality Inspection Tools and Equipment ensure that our products will meet customers' specifications.

- Our in-house Water Treatment System reduces our utility usage and the carbon footprint to the environment.

- We have standard Shipping Containers for reduction of handling and standard quantities for your unique parts. Our Bulk Containers are reused often to support our GREEN thinking!

Facility

Facility

Manufacturing: 86,500 sq. ft.

Office: 2,000 sq. ft.

Property: 10 Acres (with room for growth)

Q.C. Inspection

- Vision System - Keyence (2)

CNC CMM Unit – Hexagon

CNC CMM Unit – Hexagon- CMM Unit – Reflex by Brown & Sharp

- SPC ProLink Monitoring Systems (5)

- Crush Tester - Carver

- Crush Tester - Forney

- Hardness Tester - Wilson (2)

- Hardness Tester - Misawa Seiki

- Visual Comparator - Gauge Master

- Digital Micrometers – Mitutoyo (Multiples)

- Digital Bore-Micrometers – Mitutoyo (Multiples)

- Many Parts Specific Gauges

Molding/Compacting

Molding/Compacting

- 750 Ton – Gasbarre Multi-Level Press

- 550 Ton - Gasbarre Multi-Level Press

- 500 Ton – Best Press

- 220 Ton – Gasbarre Standard

- 200 Ton – Gasbarre Standard (3)

- 200 Ton – Gasbarre DIE - SET (2)

- 100 Ton – Gasbarre Standard (3)

- 100 Ton – Stokes

- 60 Ton (Sizing) – South Bend

- 60 Ton – Gasbarre Standard (2)

- 30 Ton – Gasbarre Standard (2)

- 20 Ton – Gasbarre Standard

Atmosphere

- Endothermic Gas Generator – Abbott VS & Capacity

- Endothermic Gas Generator - Lindberg, 3000CFH (2)

Sintering

- 14", 3 Zone Furnace - J.L. Becker

- 18" Furnace - Sinterite

- 18" Furnace - Abbott

- 24" Furnace - Sinterite

- 24", 6 Zone Furnace - Abbott

- Cooling Tower - Marley Aquatower (Dual)

- Cooling Tower - Sinterite (Dual)

Secondary Machining

- Dual Spindle w/Gantries – MW120 Murata (2)

- Machining Center – VC-3600 Doosan (2)

- CNC Lathe w/UR Robot – GT-75 Omni-Turn

- CNC Lathe – GT-75 Omni-Turn (5)

- CNC Lathe – Geno SL-400 Okuma

- Machining Center – Proto-Trak VMC-2

- CNC Lathe Auto Feed – Takamaz XL-100

- Hone - Sunnen (3)

- Quality Control Monitoring – Keyence (2)

On-site Specialties

- Steam Treating

- Tumble (Grit) Blaster- Gibson (2)

- Supersheen Tumbler - Almco

- Tumbler - Ultra Matic & Tumbler - Honite

- Vibratory Tumbler - Sample

- Oil Dip Conveyor (2)

- Oil Impregnator System (2)

- Oil Tank - Husky (2)

- Spin Dryer (2)

Support Equipment

- 2023 Peterbilt w/ 14' Box (for parts transfer)

- 2008 Chevy 3500 Flatbed (for parts transfer)

- 2012 Chevy 1500 Pick-up (for tooling & service)

- 3,000 - 4,500 lb. Fork Trucks (4)

- Air Technologies Compressors (60hp, 50hp & 25hp)

- 100-Kilowatt back-up Gas Generator

Tool Room Equipment

- 2 Lathes, Vert. Mill - Sharp,

- Surface Grinder w/ Precision Tool Grinder,

- Hone – Sunnen, Heat-treat Oven - Lindberg

Secondary Processing (Outsourced)

- Heat Treatments & Coatings

- Multiple Plating’s & Finishes

- Various Types of Machining

- Other Value-Added Processing Options Available